This website has been archived from TrainWeb.org/girr to TrainWeb.US/girr.

WonderBoard Tips

For some time, I have been searching for materials and methods to scratchbuild weather proof buildings. I don't want weather resistant, I want weatherproof. I intend to leave my buildings out all year. JigStones and corrugated aluminum cans can be used for such structures but they don't lend themselves to making Santa Fe mission style building. I have tried, with little luck, to use foam cores with a cement overcoat for such buildings. Then it occurred to me that WonderBoard would make a great core material for truly rugged outdoor buildings.

WonderBoard is a concrete based sheet material that

is normally used as a backing for ceramic tile. It is nothing more

than a conglomeration of cement particles bonded with cement and

captured between two layers of fiberglass fabric.

WonderBoard is a concrete based sheet material that

is normally used as a backing for ceramic tile. It is nothing more

than a conglomeration of cement particles bonded with cement and

captured between two layers of fiberglass fabric.

The material is porous and it will soak up moisture, but because it is made of cement it is not degraded by moisture. It therefore can make a rot free core for structures that can survive out of doors. It will need to be sealed to prevent intrusion of moisture so that subsequent freezing won't tear the material apart. This can be done with a layer of stucco, mortar or grout.

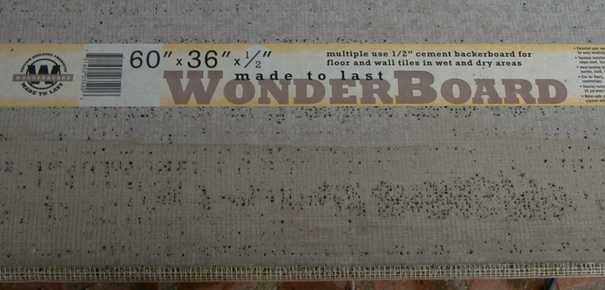

WonderBoard usually comes in 3' x 5' sheets either 1/2" or 1/4" thick. Both thicknesses are useful in building construction. You can find WonderBoard in most home improvement stores in the ceramic tile section for about $9 a sheet in the 1/4" thickness.

Contents

Cutting WonderBoard

WonderBoard is easily shaped, straight cuts are

straightforward. The fiberglass cloth on one side is simply scribed with a

utility knife and the board will break easily on the scribe. Then

the sheet is folded on the mesh on the other side and the knife is

used again to cut the second mesh. Even relatively narrow strips

can be scribed off a whole sheet.

WonderBoard is easily shaped, straight cuts are

straightforward. The fiberglass cloth on one side is simply scribed with a

utility knife and the board will break easily on the scribe. Then

the sheet is folded on the mesh on the other side and the knife is

used again to cut the second mesh. Even relatively narrow strips

can be scribed off a whole sheet.

WonderBoard is really hard on regular utility knives. A carbide tipped scribing tool will last longer, but if you have replacement blades a regular knife works well enough.

Since the material is made of little chunks of concrete, don't expect a completely clean cut. You may have to use a pair of pliers to remove a little extra material here and there.

[ Top ]

Shaping WonderBoard

More complex

shapes are possible in WonderBoard as well. This row of arches was

formed with the aid of a plywood tool. It

is possible to break out large sections with only small sections

left between them. Windows can be made the same way.

More complex

shapes are possible in WonderBoard as well. This row of arches was

formed with the aid of a plywood tool. It

is possible to break out large sections with only small sections

left between them. Windows can be made the same way.

The tool is cut in the desired shape and then used to outline the cut in pencil on BOTH sided of the material. Then the tool is used to guide the scribing knife on BOTH sides of the material.

Since a line that isn't straight cannot be simply bent, the removal method is a bit more crude. The wood tool is placed underneath the WonderBoard sheet aligned with the scribe marks and a hammer is used to pound out the undesired material. The tool serves to keep the desired material from breaking while the undesired material is literally sheared out. The cut is a little rougher than the scribe and break method, but it works.

Ron Wenger wrote to say that he uses a sabre saw to cut WonderBoard. This works too, WonderBoard cuts easily but it is hard on the saw blades. Have spares handy. The stuff can be drilled with a masonry drill to allow a clean start for a sabre saw.

[ Top ]

Sealing Cut Edges

The broken edges of

WonderBoard are very porous and should be sealed. The easiest method

is to seal them with mortar or grout. The pieces should be sealed

BEFORE a building is assembled. In the process, the edges will also

be squared up.

The broken edges of

WonderBoard are very porous and should be sealed. The easiest method

is to seal them with mortar or grout. The pieces should be sealed

BEFORE a building is assembled. In the process, the edges will also

be squared up.

I use RapidSet Cement All to seal the edges but any good mortar mix should do. The first layer of sealing material should be mixed quite wet. The broken edge should be propped facing upward and wetted with a spray of water. The wet cement mixture can be poured or ladled on. It will soak down into the broken edge and strengthen the edge while providing a base for a thicker mortar that is used to square up the edge.

As the cement mix is thickening, it can be applied with a popsicle stick or other tool to build up the edge and square the corners. After the cement has set for half and hour or so, it can be shaped further with a small tool.

Don't to concerned about excess cement mix that is slopped around. After the cement has been applied, scrape off the excess and spray the WonderBoard surfaces with water from a pump bottle. The excess cement will wash right off. Before the cement fully sets, after a half hour or so, scrape it off the sealed edges to further square them. A light spray of water will soften the surface to allow it to be smoothed.

[ Top ]

Building Construction

I knocked this little test building together to see

if I could assemble a building entirely from cement. I was

successful to some extent. It is clear that it would have been

easier if the walls and floor had been preassembled with small dabs

of adhesive of some kind. Mortar is a little difficult to use as it

has no strength until it sets up and working on the building before the cement has set will

disturb previously made joints. It might also be desirable to include some reinforcement in the joints in the form of a wire or plastic mesh. This building was strong enough without it, but over time, cracks may propagate and break a whole joint. I didn't do that in this building, I'll be evaluating the technique in later structures.

I knocked this little test building together to see

if I could assemble a building entirely from cement. I was

successful to some extent. It is clear that it would have been

easier if the walls and floor had been preassembled with small dabs

of adhesive of some kind. Mortar is a little difficult to use as it

has no strength until it sets up and working on the building before the cement has set will

disturb previously made joints. It might also be desirable to include some reinforcement in the joints in the form of a wire or plastic mesh. This building was strong enough without it, but over time, cracks may propagate and break a whole joint. I didn't do that in this building, I'll be evaluating the technique in later structures.

The building wasn't

originally intended to be anything, it was just assembled from

scraps of 1/4" WonderBoard on an 1/2" WonderBoard base. However, it

looked that it might actually make a usable building. By adding a

larger base of 1/4" WonderBoard (double thickness under the apron),

a rock roof and by squaring up the doorways it will make an acceptable

auto repair shop.

The building wasn't

originally intended to be anything, it was just assembled from

scraps of 1/4" WonderBoard on an 1/2" WonderBoard base. However, it

looked that it might actually make a usable building. By adding a

larger base of 1/4" WonderBoard (double thickness under the apron),

a rock roof and by squaring up the doorways it will make an acceptable

auto repair shop.

The walls have been coated with RapidSet to simulate stucco. Once the RapidSet is partially set, a light rubbing brings out the sand and roughs up the surface a little. The apron's cement overcoat has been scribed to simulate cracked concrete.

Even this little building is very heavy, probably about 10 lbs. It is clear that some attention needs to be paid to minimizing the materials used on larger structures so that they aren't so heavy that they cannot be moved around.

Check back in a month or so for further progress on a freelance Santa Fe mission style passenger station.

[ Top ]

This page has been accessed times since 5 Nov 00.

Created Nov 5, 2000

Last Updated Jan 20, 2001

24 Nov 00

24 Nov 00