This website has been archived from TrainWeb.org/railengineering to TrainWeb.US/railengineering.

|

Home

|

Track inspection

A site visit to Edinburgh was undertaken to a company called VAE Rail. The purpose of the

visit was to inspect a major S&C layout that was being constructed. This was to be used in

the Leeds First project, and we were there to ensure that the actual crossing matched the

design.

S&C basics

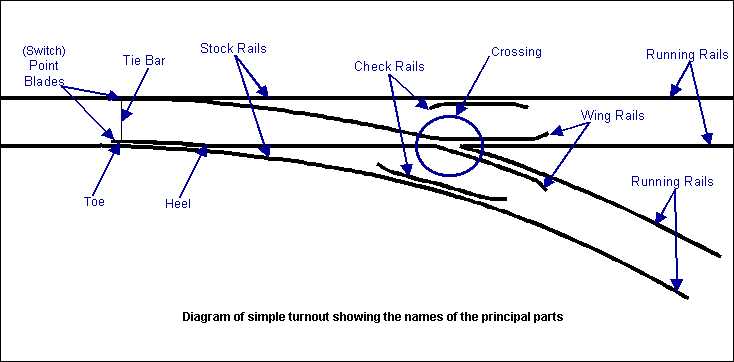

S&C is used to allow a train to pass from one line to another. A basic diagram can be

drawn to show how a standard S&C layout works. This is shown in FIG. XXX.

The moving part of the turnout is the switch "blade" or "point", one for each route. The

two blades are fixed to each other by a tie bar to ensure that when one is against its stock

rail, the other is fully clear and will provide room for the wheel flange to pass through

cleanly. Either side of the crossing area, wing and check rails are provided to assist the

guidance of the wheels through the crossing.

The crossing can be cast or fabricated. Rails are usually made of steel with a large iron

content but a little manganese is added to crossings and some heavily used rails to increase

resistance to wear. An example of a cast manganese crossing can be seen below.

Not only did we inspect the layout, but we also had a guided tour around the factory where

all rail is machined. This was a useful visit since I actually got to look at some of the

design issues of S&C. For example, I looked at the transition rail as seen in Fig XXX, the

difference between a shallow bearer and a normal bearer as seen in Fig. XXX and saw the

different types of crossings available as mentioned in the last paragraph.

|