This website has been archived from TrainWeb.org/railengineering to TrainWeb.US/railengineering.

|

Home

|

Deficiency and Cant

Where curves are present, it is not unusual to find that cant has been designed into them.

That is, the outside rail of a curve is higher than the inside rail. This is to help

cornering, to ensure even wear of the rails and to assist passenger comfort.

Deficiency is what the passenger actually feels; the bumps and jolts the train makes due to

the track. An equation can be used to calculate how much cant can be used on a curve, and also

indicates the deficiency.

Where:

So, for example, if the radius was to be 4000 m and the running line speed was 75 mph, the

calculation would be:

E + D = 16.62

As the TDM states that the maximum cant to deficiency ratio allowed is 73:27.

So therefore:

The cant = 73% of 16.62 = 12.13 mm

which leaves deficiency to be 4.49 mm.

The equation used for cant and deficiency calculations shows the relationship that with

decreasing radius, and constant speed, the required cant becomes greater. Likewise, for

increasing speed and constant curve radius.

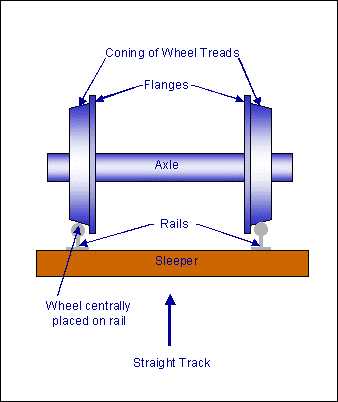

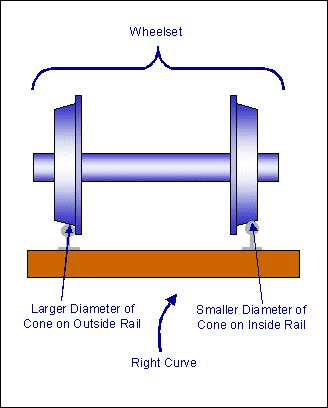

All rails found in plain line have an incline of 1:20. This is to ensure that the forces

acting on the rail are perpendicular between the wheel and the rail. To understand this,

it is best to look at the basics of train wheels.

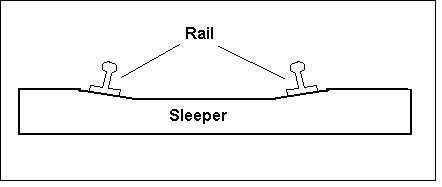

Angled sleepers Fig 70 shows exactly what is meant by angled sleepers. The angle being created by the sleeper and not the rail.

Angled base plates If the sleeper cannot be manufactured with an angle in it, for example it is a wooden sleeper, the baseplates on which the rail sits can be angled to a 1:20 incline. Fig 71 shows a standard baseplate and the angle can clearly be seen sloping downward to the right.

If the line speed is mostly one value, equilibrium cant can be designed into the rail. This is were a passenger would not be aware that they would be travelling around a corner. The explanation for this is that the passenger would be level, relative to the train, but not to the ground. The same would apply to a cup of water. It would not spill as it would be level, in relation to the train.

However, it is not always ideal to have equilibrium cant on corners. This may be if there are other locomotives running on the same line. If a freight train was to go around the rail at a slower speed than the passenger train, more force would be exerted onto the lower rail. This would cause more wear of the rails and would also cause a loud squealing noise from the wheels. This is not ideal, especially if it is near a built-up or residential area. The amount of complaints from people living nearby would be phenomenal. The reason for this squealing is that the inner wheel uses the outer edge of its tyre to reduce the travelled distance during the passage round the curve. The flange of the outer wheel will only touch the rail if the movement of the train round the curved rail is not in exact symmetry with the geometry of the track. This can occur due to incorrect speed or poor mechanical condition of the track or train.

Rail lubrication Rail greasing is used on the railway infrastructure to ease the passage of wheels on curves. The way in which the curves are lubricated is by a cylinder located at the start of the curve for one directional running, or at each end for bi-directional running. The wheel of the train runs over a grease nipple located on the track and the grease spreads onto the wheel. The grease is then spread along the length of the curve by the train. The reason for this is to ensure the rail lasts for as long as possible. It is important to ensure that the amount of lubricant applied is exactly right. Too much will cause the wheel to become contaminated and will lead to skidding and flat spots. There will always be some slippage between the wheel and rail on curves but this will be minimised if the track and wheel are both constructed and maintained to the correct standards.

|